How Slow-Moving Inventory is Strangling Your Profitability

If you manage an inventory, you’re fighting a war on multiple fronts. While you focus on visible challenges like carrier rate hikes, labor shortages, and peak season chaos, a silent internal enemy is quietly undermining your entire operation.

That enemy is your slow-moving and static inventory.

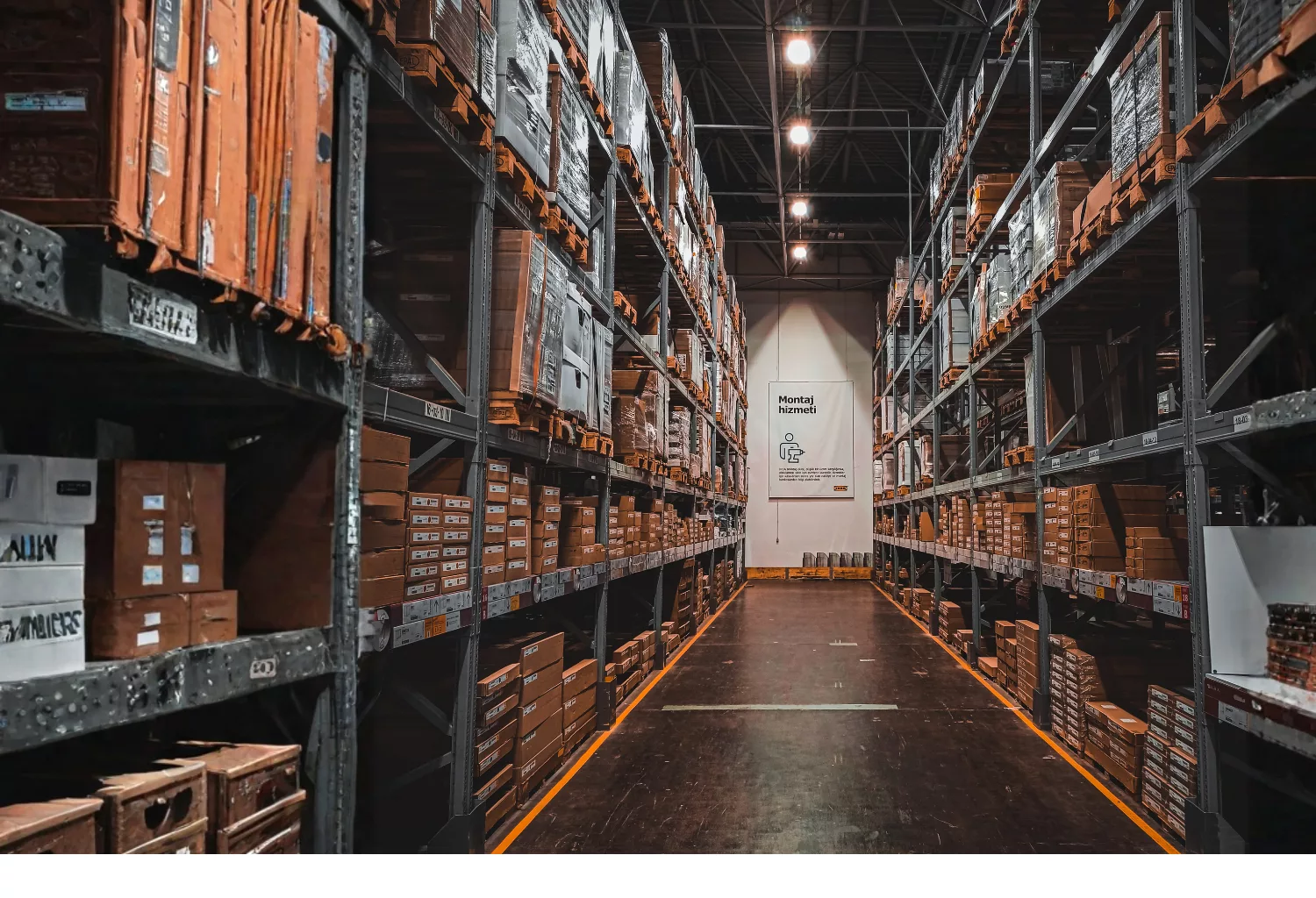

Think of it not as static stock, but as a malignant presence inside your warehouse. It’s not passive, it’s actively hostile to your efficiency, profitability, and team morale. Like a blocked artery, it forces your entire system to work harder, slower, and at a higher cost.

The True Cost of “The Clog”: Beyond the Balance Sheet

The financial write-down is only the surface of the problem. Beneath it lies a deeper operational drag that erodes performance over time. Let’s break down this “clog” and its direct impact on your business.

1. The Real Estate Heist

The Problem: Every pallet of unsold goods from two seasons ago occupies valuable space that could generate revenue today. According to the Warehousing Education and Research Council (WERC), over 15% of the average warehouse’s footprint is filled with slow-moving or obsolete inventory.

This isn’t just lost space, it’s lost opportunity. By clearing this clutter, you immediately increase your storage capacity without adding a single square foot of warehouse space.

2. The Labor Tax

The Problem: Your team doesn’t simply walk past this inventory; they manage it constantly. They count it during audits, move it to access fast-movers, and waste valuable minutes on longer pick paths. Studies from the Material Handling Institute (MHI) show that reducing inventory clutter can improve picker productivity by 10–20%.

This acts as a hidden tax on your most flexible cost labor. Removing the clutter effectively gives your team a permanent productivity boost.

3. The Data Corruption Effect

The Problem: When your warehouse is overstuffed, data accuracy plummets. Items get lost, miscounted, or misplaced, which leads to false stock-outs, shipping errors, and unhappy customers.

A leaner inventory is a more reliable one. Eliminating excess stock is the first step toward achieving flawless inventory accuracy.

The Strategic Pivot: From Cost Center to Profit Engine

For years, liquidation was seen as a necessary evil. Now, it has evolved into a strategic lever that builds agility, resilience, and profitability. The goal isn’t merely to clear space, it’s to fund future growth.

This is where the narrative shifts from problem to solution.

At Ozeol, we’ve built a platform that transforms your biggest operational liability into a competitive advantage. Our process empowers modern supply chain leaders who know that speed and capital define success.

Ozeol: Turn Your Greatest Liability into Your Sharpest Advantage

We help you convert inventory clutter into cash and clarity fast. Here’s how we do it:

1. Intelligent Assessment

We conduct a transparent, data-driven valuation of your slow-moving stock so you know exactly what recovery to expect before you commit.

2. Seamless Extraction

Our team handles everything from scheduling pickups to managing logistics while giving you full visibility from your dock to the final destination.

3. Value Maximization

Through our global B2B buyer network, your products reach the right markets, maximizing recovery value and protecting your brand reputation.

4. Operational Liberation

The result isn’t just a transaction, it’s transformation. You gain a cleaner warehouse, faster fulfillment, a more motivated team, and capital ready to reinvest in what sells now.

The question is no longer, “Can we afford to liquidate?”

It’s, “Can we afford not to?”

Every day that stagnant inventory sits in your warehouse, it quietly drains your resources space, labor, and opportunity.

So, are you ready to eliminate the clog and unlock your warehouse’s full potential?

Choose Your Path to a Leaner, More Profitable Operation

Don’t let your warehouse work against you.

Take the first step toward a leaner, more profitable operation.

Let Ozeol help you clear your stock and reclaim your warehouse efficiency, click here to get started.